Natural Capital

Driving Change: Advancing Green Infrastructure Initiatives

We are increasing our emphasis on developing efficient and sustainable solutions for executing large and complex industrial infrastructure projects. By leveraging our expertise across various business segments, we are actively working to reduce our carbon footprint and preserve natural resources. These efforts align with the transition to clean energy, supporting India’s Net Zero ambitions.

We pledge to minimise our consumption of natural resources, reduce pollution, protect diversity and sustain the environment, leading the way towards a more sustainable future.

SDGs Impacted

As the Tata Group sets ambitious targets for environmental sustainability, our businesses not only align with India’s vision for sustainability and climate action but also lead the global endeavour to combat climate change and foster environmentally responsible growth.

The Tata Sustainability Group (TSG)

Acts as a Centre of Excellence and primary resource hub for sustainability within the Tata Group. Tata Projects is closely aligned with the Group’s overall mission to diminish India’s energy imports and bolster national self-reliance by repurposing waste and tapping into locally available renewable resources.

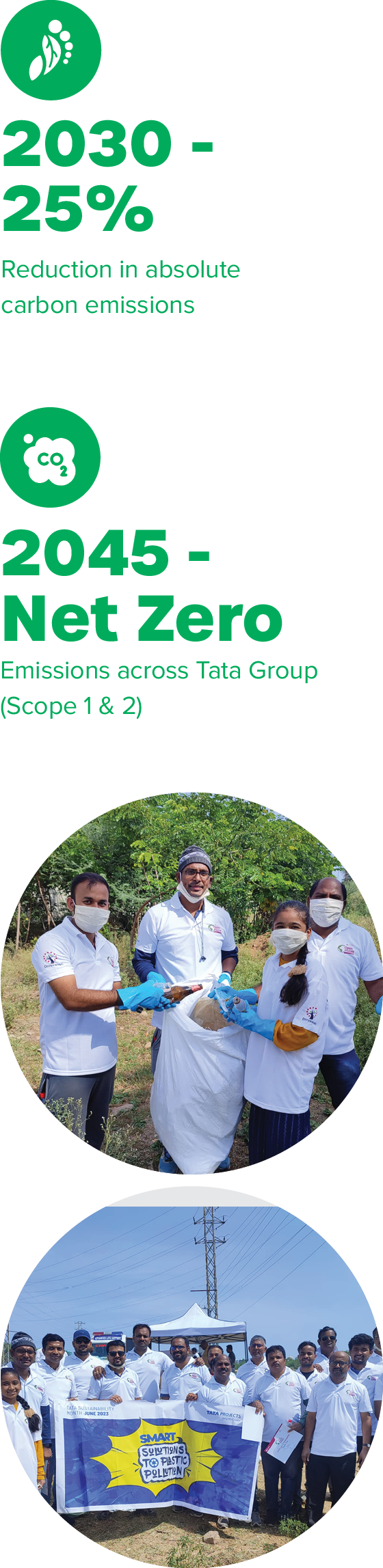

Project Aalingana

Launched by the Tata Group in 2022, remains our guiding North Star in our Sustainability Journey, setting both mid-term and long-term goals for the Company. Aalingana outlines the Tata Group’s approach towards planet resilience, its aspiration of Net Zero by 2045, and the vision of securing the future by innovating today.

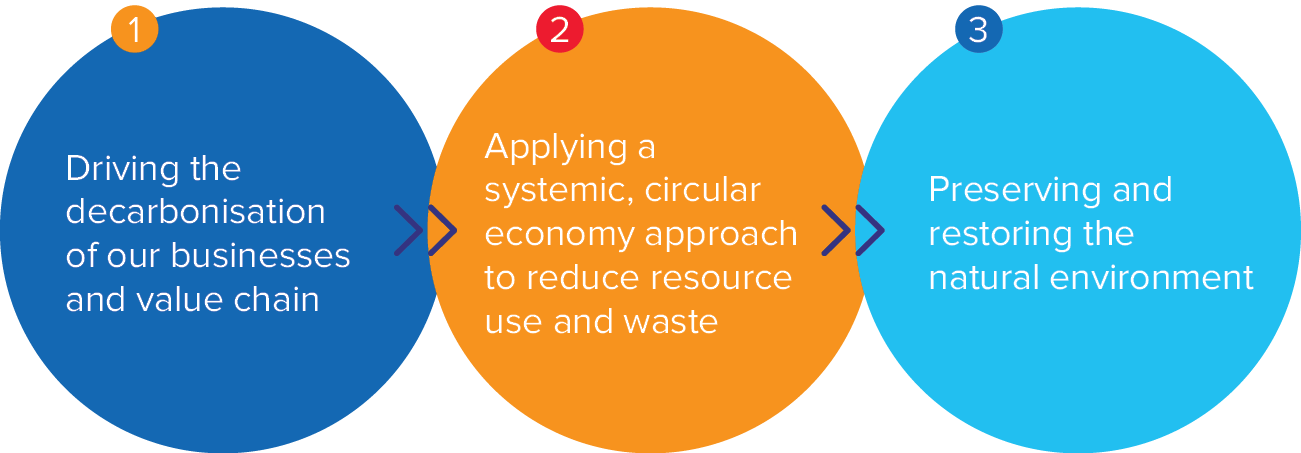

Project Aalingana is committed to embed sustainability into our business strategy by focusing on three inter-connected pillars.

To meet the commitment to the Aalingana goals and targets, Tata Projects’ functional EPM process for sustainability is defined based on materiality exercise. Sustainability-related KPIs (Enterprise, SBG, SBU, Site) have been identified at the corporate level, and site-level initiatives are conducted, besides monitoring every site monthly.

Sustainable Construction Practices

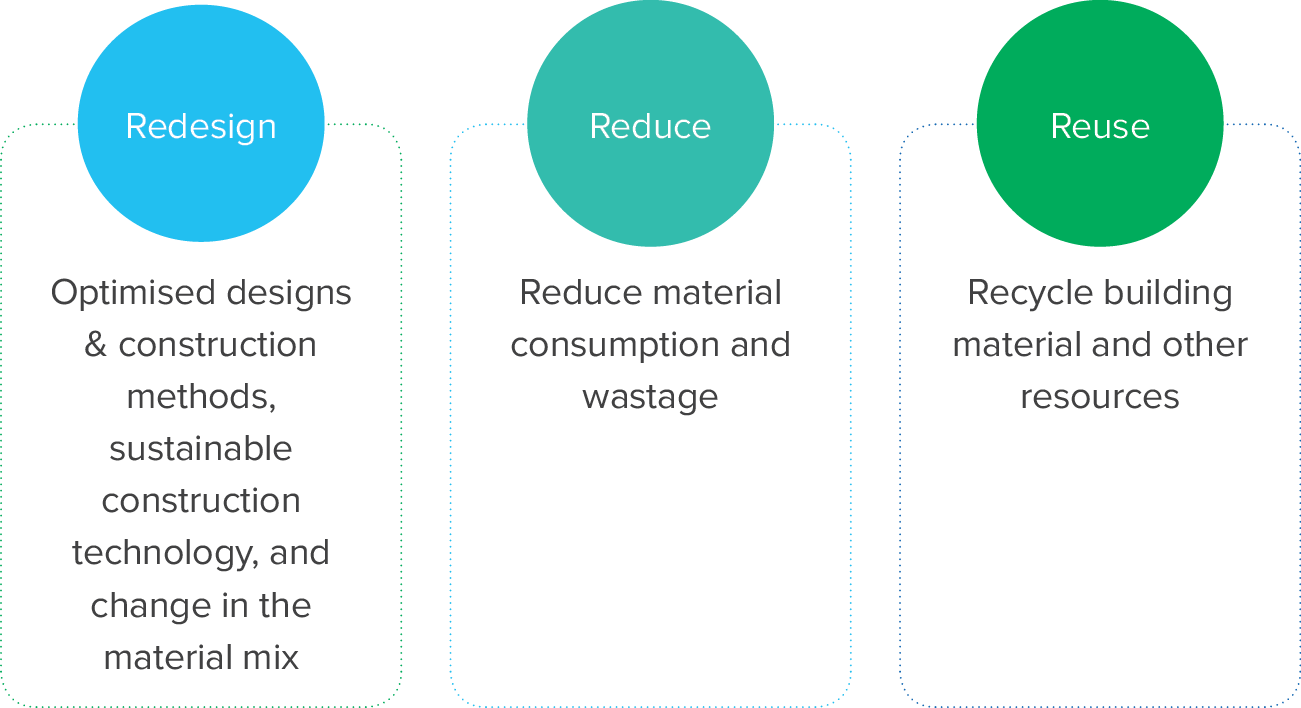

At Tata Projects, our core focus encompasses various facets, including material management, the adoption of alternative and sustainable materials, modular construction techniques, and efficient water and waste management. Additionally, we’re committed to fostering a sustainable supply chain by promoting green vendors.

In terms of material management, we’ve implemented robust systems to track and manage material consumption across different categories. This enables us to ensure optimal utilisation of materials throughout our operations, aligning with our commitment to advance the circular economy agenda.

Tata Projects’ approach to sustainable construction rests on three pillars.

Redesign, Reduce, and Reuse.

Tata Projects has adopted sustainable construction practices that prioritise judicious use of natural resources, minimise environmental impact, and uphold ecosystem preservation. We invest conscientiously to ensure sustainable operations, recognising the importance of natural capital, which includes both renewable and non-renewable resources such as raw materials, land, and water. Our sustainability initiatives are aimed at achieving tangible and enduring outcomes. We proactively work to mitigate our environmental footprint by emphasising on conservation efforts and optimising the usage of natural resources. By doing so, we play a meaningful role in combatting the global fight against climate change and contributing to a more sustainable future.

Environment

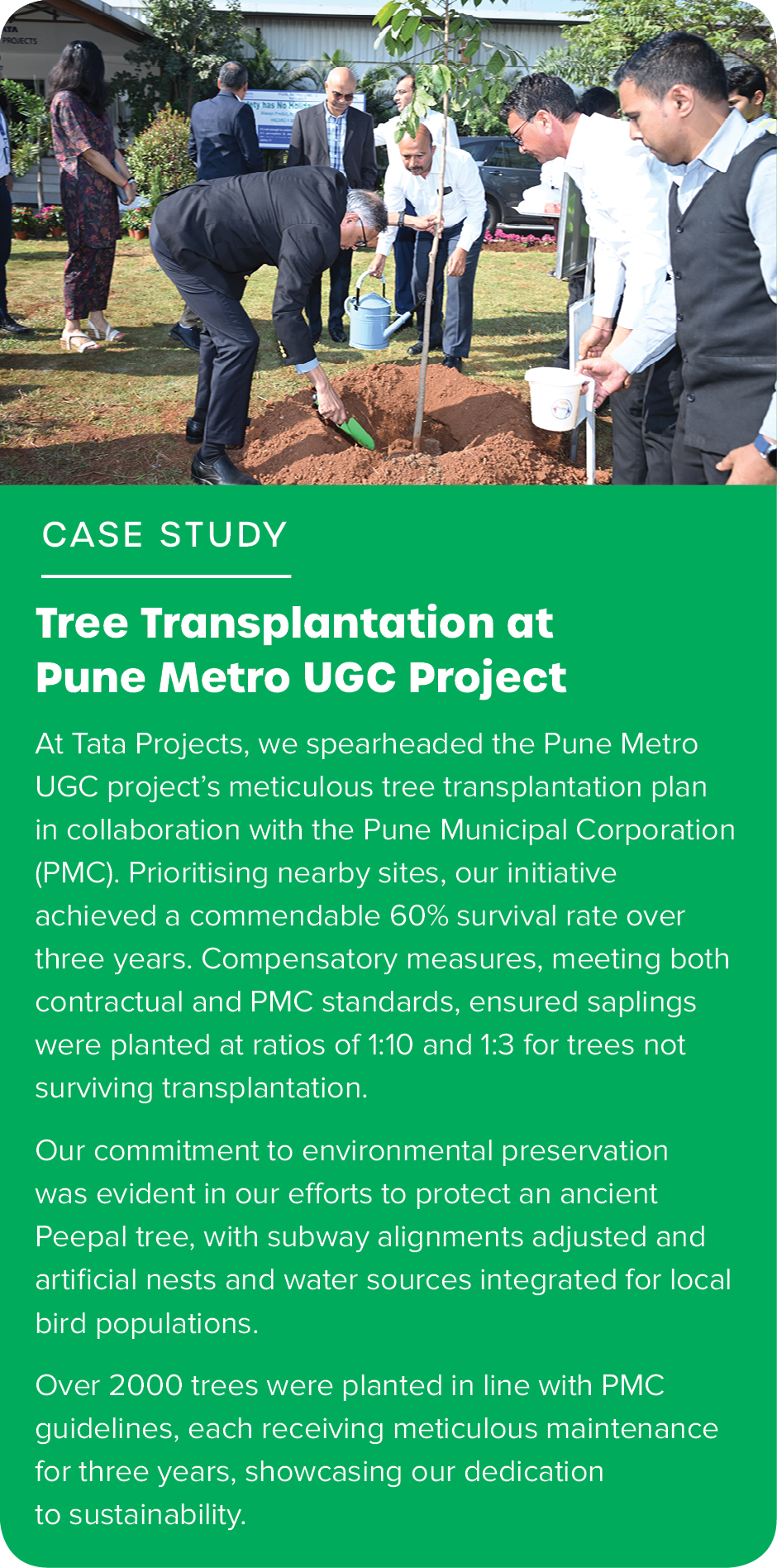

Green Thumb Initiative

Tata Projects’ Green Thumb initiative, launched in 2016 on World Environment Day, aims to restore India’s green cover and counter the effects of climate change. Initially an employee engagement effort, Green Thumb has evolved into a comprehensive environmental conservation programme. Through this initiative, individuals pledge to plant trees, fulfilled by Tata Projects at project sites nationwide. Operating on a unique online model, 'You click, we plant,' Tata Projects attributes trees to clicks received on its microsite. Planting trees is now easier and faster with Green Thumb.

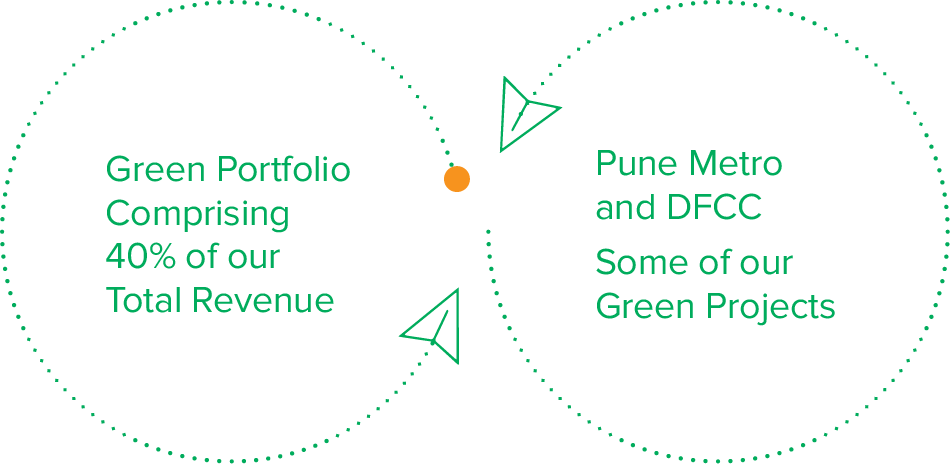

Green Portfolio

Tata Projects is ambitiously driving impactful change, revolutionising logistics and spearheading critical infrastructure projects like dams. Our expertise spans diverse sectors, including metro rail systems, sewer networks, airports, solar energy, semiconductor manufacturing, and smart lighting. Landmark achievements include iconic projects like the Pune Metro and Dedicated Freight Corridor.

With our green portfolio now comprising 40% of revenue, we are committed to even greater strides in sustainable growth.

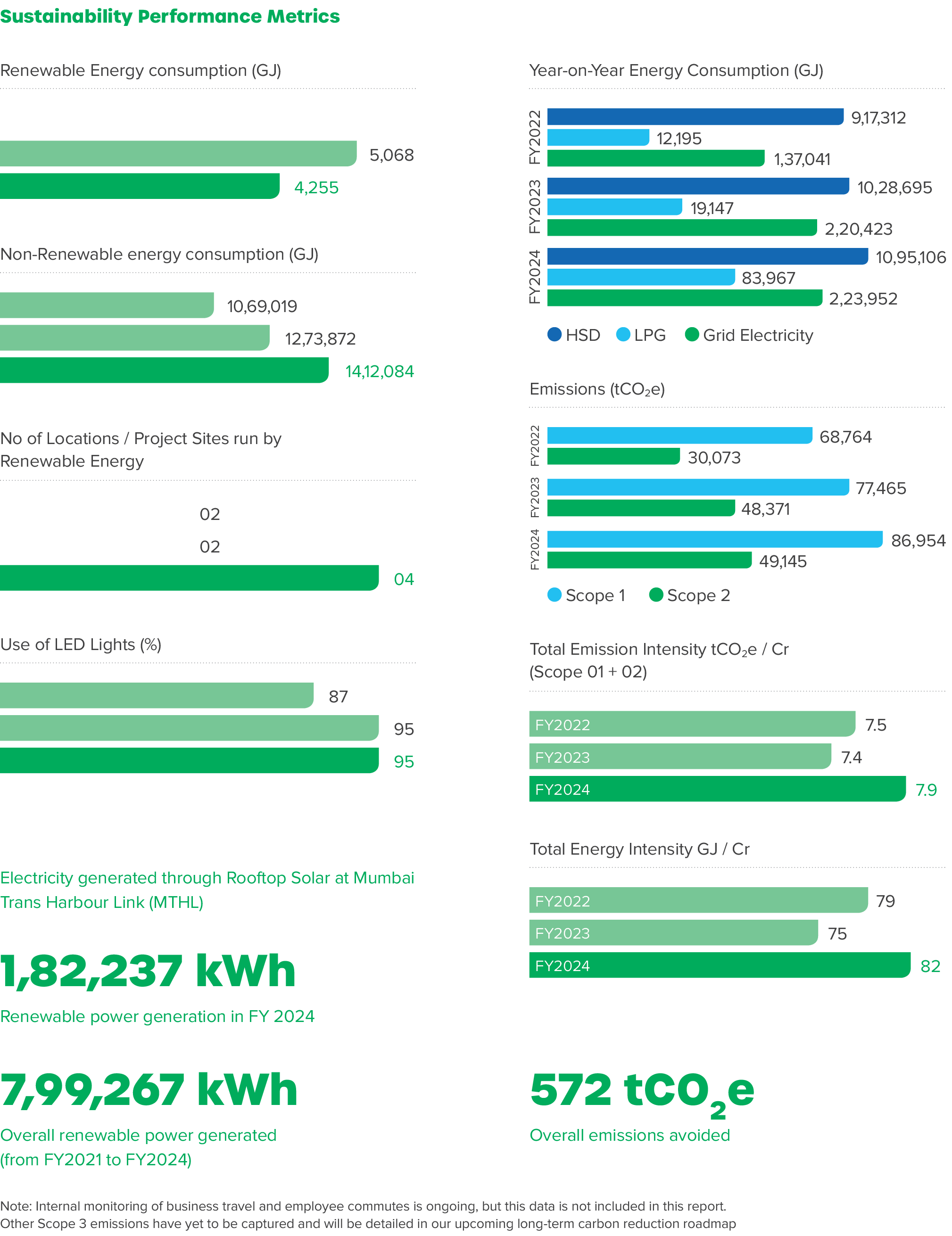

Below are the key measures we are implementing to reduce Greenhouse Gas Emissions.

Reducing Energy Consumption and Increasing the Use of Renewable Power

- Mandating grid connectivity at plant sites

- Discouraging usage of DG Sets

- Increasing renewable power usage at plant sites (for e.g., the TMU & MTHL made extensive use of solar power)

- Monthly monitoring and tracking of energy consumption (as per yearly targets) and working with the site SPOCs to meet targets

We have established a 990 KW solar plant at The Manufacturing Unit (TMU) in Nagpur, which generated 8,92,182 kWh of electricity over the past year.

Enhancing Resource Efficiency

We identified KPIs for reducing emissions and energy intensity in our operations and implemented key measures to enhance resource efficiency and performance.

- Utilising BSIV & above norms for energy-efficient equipment

- Using LED and solar lights for lighting purposes

- Variable Frequency Drive (VFD) implemented by the Fleet Team

- Increasing renewable energy use to reduce carbon emissions

- Organising plantation drives at project sites (for e.g., the Green Thumb initiative)

Implementation of IOT

Tata Projects is identifying the process of capturing data on air, water, and energy parameters. This process will be implemented at all our plant sites to conduct live monitoring of the consumption of these natural resources and ensure all parameters are within statutory levels.

Strategic partnership with CSIR

Our shift to cleaner alternate energy remains at our core, and we are finding innovative pathways to reach our goal. During the year, we signed an MoU with the Council of Scientific and Industrial Research-Indian Institute of Petroleum (CSIR-IIP) to jointly work towards clean energy solutions. The MoU aligns with our mandate to reduce India’s energy imports and enhance national self-reliance by repurposing waste and under-utilised local renewable carbon resources.

- We are exploring clean energy solutions such as room-temperature biodiesel across plant sites. During the year, biodiesel blend usage was implemented at Garhmukteswar, Meerut, and will be implemented at other sites based on availability.

- We were exploring the use of the by-product Green Diesel from the existing DILSAAF (Drop-In Liquid Sustainable Aviation Fuel and Automotive Fuel) pilot plant in Dehradun and proposed a commercial-scale demonstration.

We established a biodigester unit at the NIAL site to convert food and organic waste into gas and fertilisers.

Emission Reduction and Management Strategies

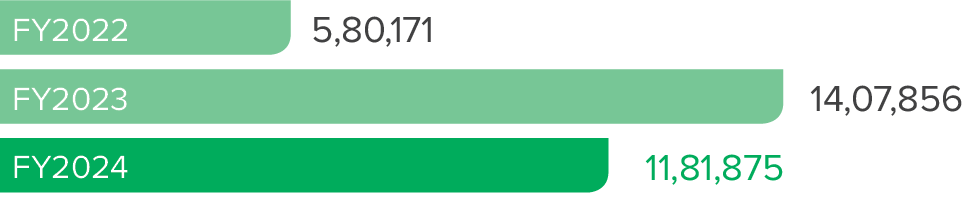

11,81,875 kWh

Solar energy generated (FY2024) at enterprises level.

As a responsible corporate entity in an energy-intensive sector, at Tata Projects, we actively devise strategies to manage energy and emissions risks. Our focus on energy conservation involves

TMU Nagpur’s solar-powered roof produces green towers and supply items, cutting reliance on fossil fuels and reducing project carbon footprints.

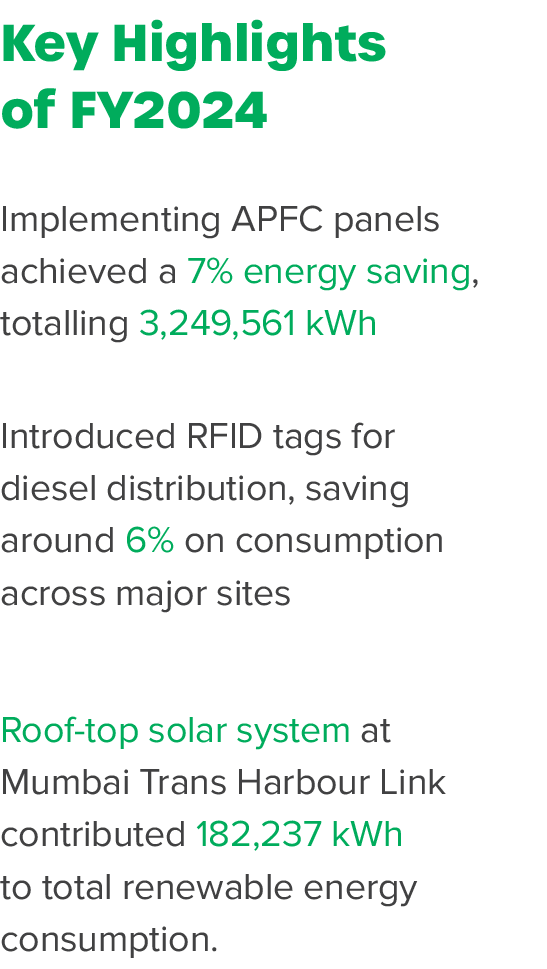

Technological, Operational, and Behavioural upgrades, including implementing APFC panels, LED lighting, VFD-controlled hoists and cranes, inverter welding machines, and grid power optimisation. Moreover, we invest in renewable energy sources, such as rooftop solar systems and solar streetlights, and leverage technology for efficient energy monitoring and diesel distribution, yielding substantial savings and environmental benefits.

Tata Projects Limited has significantly increased its renewable energy consumption, notably establishing a 990 kW solar plant at the Manufacturing Unit (TMU) in Nagpur, generating 8,92,182 kWh over the past year. The baseline for energy consumption is set using historical data from previous years. The methodology involves collecting data through metering systems, making standard assumptions about operational efficiency, and calculating energy savings by comparing the baseline with current usage. These calculations are verified through internal audits and third-party assessments to ensure accuracy. This approach underscores Tata Projects' commitment to sustainability and responsible energy management.

Overall Solar Energy Generated (kWh) at enterprises level

Alternate Material and Modular Construction

Recognising the critical role of sand in our operations, Tata Projects collaborates with suppliers to recycle construction and demolition (C&D) waste, producing M-Sand as a substitute for natural sand. This approach reduces landfill waste and lessens our dependence on natural resources. To further minimise our environmental impact, we promote the use of alternative materials such as Fly Ash, GGBS, Fly Ash Bricks, slag cement, and PPC cement. These materials, derived from waste produced by thermal power and steel plants, require less energy to produce compared to traditional options. This makes them economically viable and helps reduce toxic emissions and environmental damage.

Key Highlights

| Raw Material (in m3) | FY2022 | FY2023 | FY2024 |

| Fly Ash | 95,794 | 99,706 | 66,30,133 |

| GGBS | 83,668 | 1,06,192 | 17,67,049 |

| Fly Ash Bricks | 1,69,81,982 | 94,83,140 | 28,42,086 |

| AAC Blocks | 4,29,303 | 28,320 | 61,053 |

| M-Sand | 5,81,387 | 7,30,960 | 9,99,826 |

| Micro Silica | 39,344 | 28,868 | 40,828 |

65,60,000 m3 Fly Ash was used in CPRR Project for concreting and backfilling activity.

Case-Study

Catalysing Change at Noida’s Upcoming International Airport

An advanced tailor-made catalyst from Nanogence Catalysts is revolutionising construction at the Noida airport, allowing for a direct reduction or substitution of up to 20% of the cement requirement. Tata Projects Limited is the airport’s EPC partner and we are spearheading this innovative approach. The material’s performance is closely monitored through meticulous control trials, focusing on key factors such as compressive strength and slump retention. Furthermore, integrating nano-level concrete packing enhances the structure’s long-term weather and corrosion resistance, ensuring durability and sustainability.

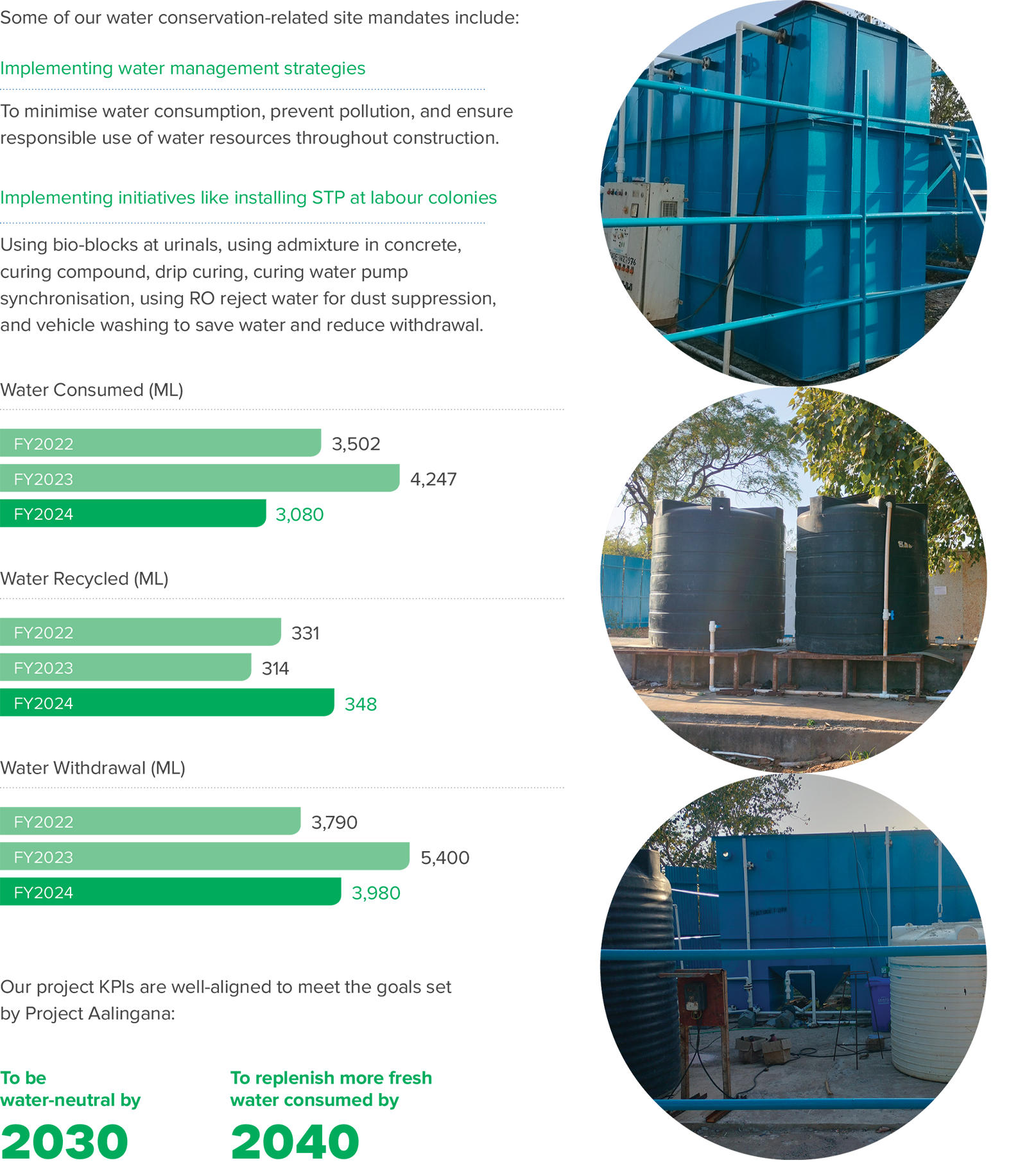

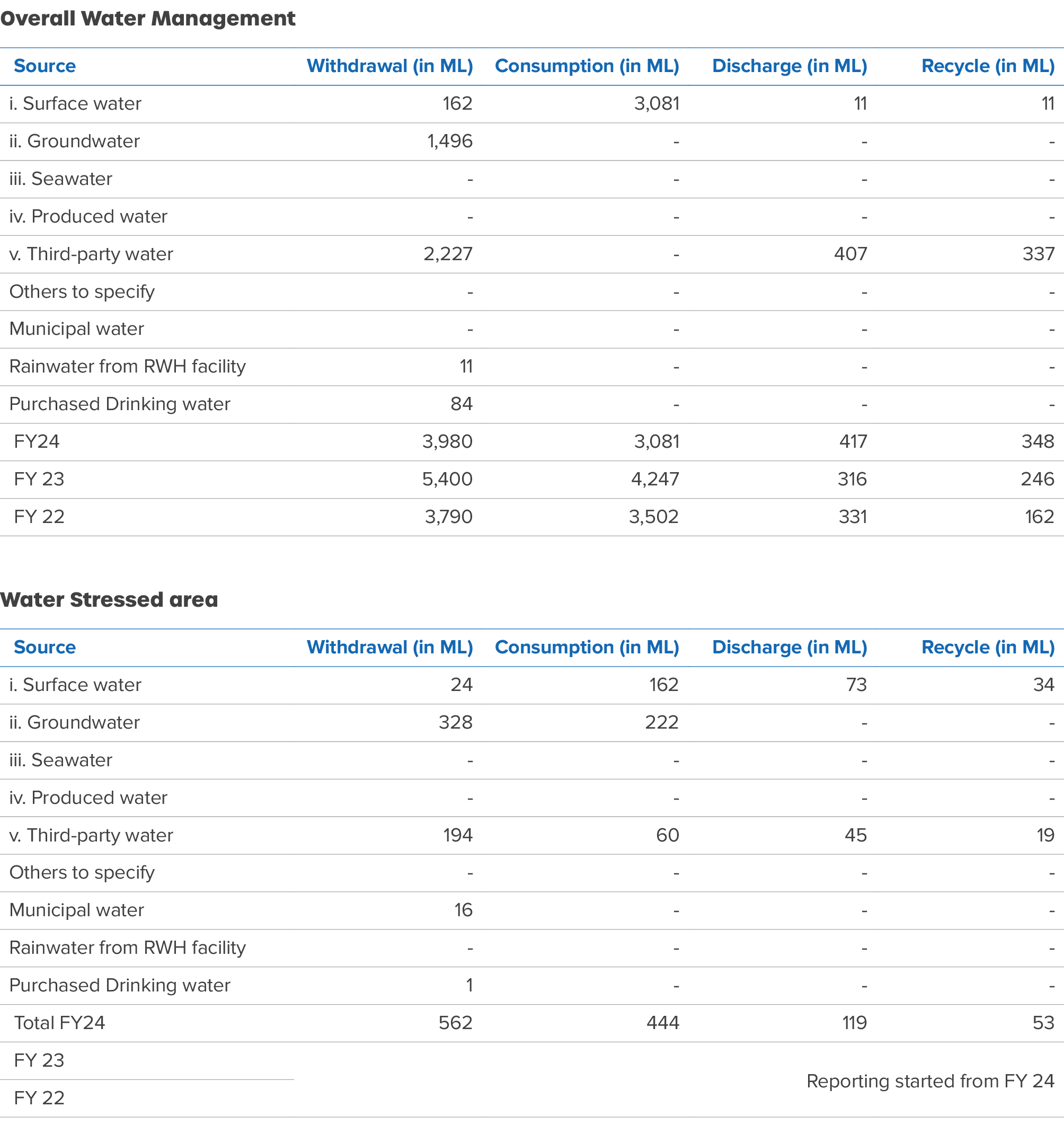

Water Management

Tackling Water Scarcity in High-Stress Areas

In our ongoing commitment to sustainability, we have identified several critical regions facing significant water stress. These areas include FGD Vallur, HRRL Barmer, CMRL, CPRR, TMU, First Solar, and DFCC. In response, we have implemented a series of advanced water management techniques designed to minimise water usage and promote recycling. Key initiatives include:

Water Avoidance Strategies: Adoption of water-reducing admixtures, curing compounds, and wastewater recycling processes to significantly cut down on water consumption.

Recognising the importance of precision in water management, we have also launched 20 pilot projects across these locations. These projects leverage IoT technology to monitor and control water consumption and withdrawal in real-time. This initiative represents a significant step forward in optimising resource use.

These initial steps are part of a broader strategy to establish a comprehensive water management roadmap. This roadmap will define our long-term goals and strategies for monitoring and reducing water usage across all our operations, ensuring that we remain at the forefront of sustainable development.

Waste Management

Tata Projects is focused on controlling waste management in various stages of its operations. We remain aligned with Project Aalingana’s goal of Zero Waste to landfill by 2030. In Reuse and Recycling, we place orders for required quantities as per ready for construction drawings and during execution to eliminate over-procurement. We track both hazardous waste and non-hazardous waste.

We remain aligned with Project Aalingana’s goal of Zero Waste to landfill by 2030.

Steps taken

Hazardous waste is disposed of as per statutory guidelines through authorised recyclers.

Non-hazardous waste like steel is sent to recyclers.

Cement waste is controlled by procuring through bulkers and loaded into silos of batching plants using digitalised mechanism.

Concrete waste is used to make paver blocks and earth pits, and tested cubes are used to make tanks.

During Tata Sustainability Month (TSM) month, employees received awareness materials shared by Tata Sustainability Group (TSG). Further, sustainability initiatives and activities were carried out throughout the month to engage all our employees and sensitise them towards sustainability. We also released guidelines avoiding usage of single-use plastic.

Key Highlights

| FY2022 | FY2023 | FY2024 | |

| Total solid waste generated (in MT) | 15,325 | 19,215 | 32,741 |

| Hazardous waste generated (in MT) | 1,189 | 1,818 | 1,967 |

| Hazardous waste sent to landfill (in MT) | 851 | 387 | 451 |

| Non-hazardous waste generated (in MT) | 14,136 | 17,397 | 30,774 |

| Non-hazardous waste sent to landfill (in MT) | 1,358 | 1,040 | 7 |

| Total plastic waste generated (in MT) | 240 | 267.5 | 122.6 |

| Spent / waste oil (in KL) | 27 | 49 | 6,620 |

| Spent / waste oil disposed through recyclers (in KL) | 14.77 | 20.2 | 1,511 |

| Reuse of Spent oil (in KL) | 8.7 | 1 | 1 |

Impact Mapping

We quantitatively analyse all the data from our construction sites to map out their environmental impact. We also review regular progress of our initiatives and identify further areas for improvement in all aspects of sustainability.

Reducing dependency on Natural Resources

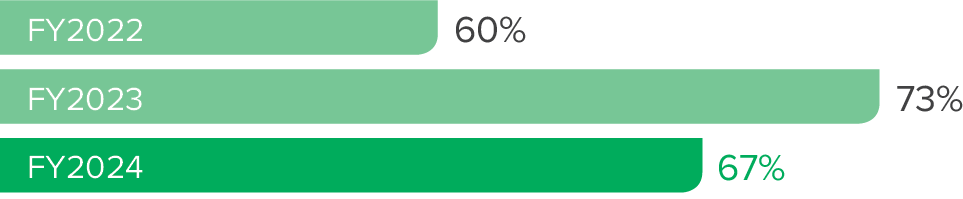

We use Manufactured Sand (Msand) instead of River sand in the all civil works wherever applicable as per % of concreting done with Msand w.r.t overall concrete production as follows:

Recycling of Waste

We recycle and reuse waste from its initial generation point, ensuring it is processed through authorised recyclers. Any remaining waste is kept in stock and will be reused or recycled as needed.

In FY2024, 18,037MT mixed waste was reused and recycled where 9327MT was reused and 8710MT was disposed through authorised recyclers.

Reduction in Non-Hazardous Waste Sent to Landfill for FY2024

We achieved a notable reduction in non-hazardous waste sent to landfills through several strategic initiatives:

- Enhanced Waste Management Practices: We partnered with external consultants for detailed waste data analysis, refining our methods to improve waste management and reduce landfill waste.

- Effective Waste Segregation and Disposal: Non-hazardous waste, such as concrete, is repurposed for paver blocks, flooring, and backfilling. This repurposing significantly lowers landfill volumes. Both hazardous and non-hazardous waste were collected on a monthly basis.

- Food Waste Management: A biodigester was piloted at the NIAL project to handle food waste, with plans for broader implementation, reducing landfill waste from food sources.

- Reduction in Plastic Waste: We introduced guidelines against single-use plastics and monitored plastic waste, complemented by a plastic waste awareness programme to further cut plastic waste.

- Increased Recycling Efforts: Enhanced recycling practices for mixed waste through authorised recyclers have significantly decreased non-hazardous waste destined for landfills.

These efforts have effectively reduced non-hazardous waste sent to landfills in FY24, with ongoing initiatives to enhance sustainability and waste management practices.

Bio-Diversity

Our policy establishes clear guidelines on biodiversity conservation. It prioritises project sites for minimal ecological impact and conducts thorough environmental assessments in advance.

Moving forward, regular monitoring and reporting on biodiversity metrics will be integrated into our project management processes. Additionally, we will also invest in employee training and awareness programmes to foster a culture of biodiversity stewardship within the organisation. We will keep updating the bio-diversity guidelines to align them with evolving industry standards and best practices, ensuring our commitment to environmental sustainability and biodiversity conservation.

Supply Chain Assessment

Tata Projects encourages its partners, contractors, and suppliers in the supply chain to reduce emissions, water, and other aspects of ESG. During their onboarding, we evaluate supply chain partners on ESG aspects and identify them as Green Vendors. Once identified, we conduct regular training for them, and encourage businesses to increase the share of Green Vendor procurement, in line with TSG guidelines and KPIs.