Manufactured Capital

Delivering High-Quality Infrastructure

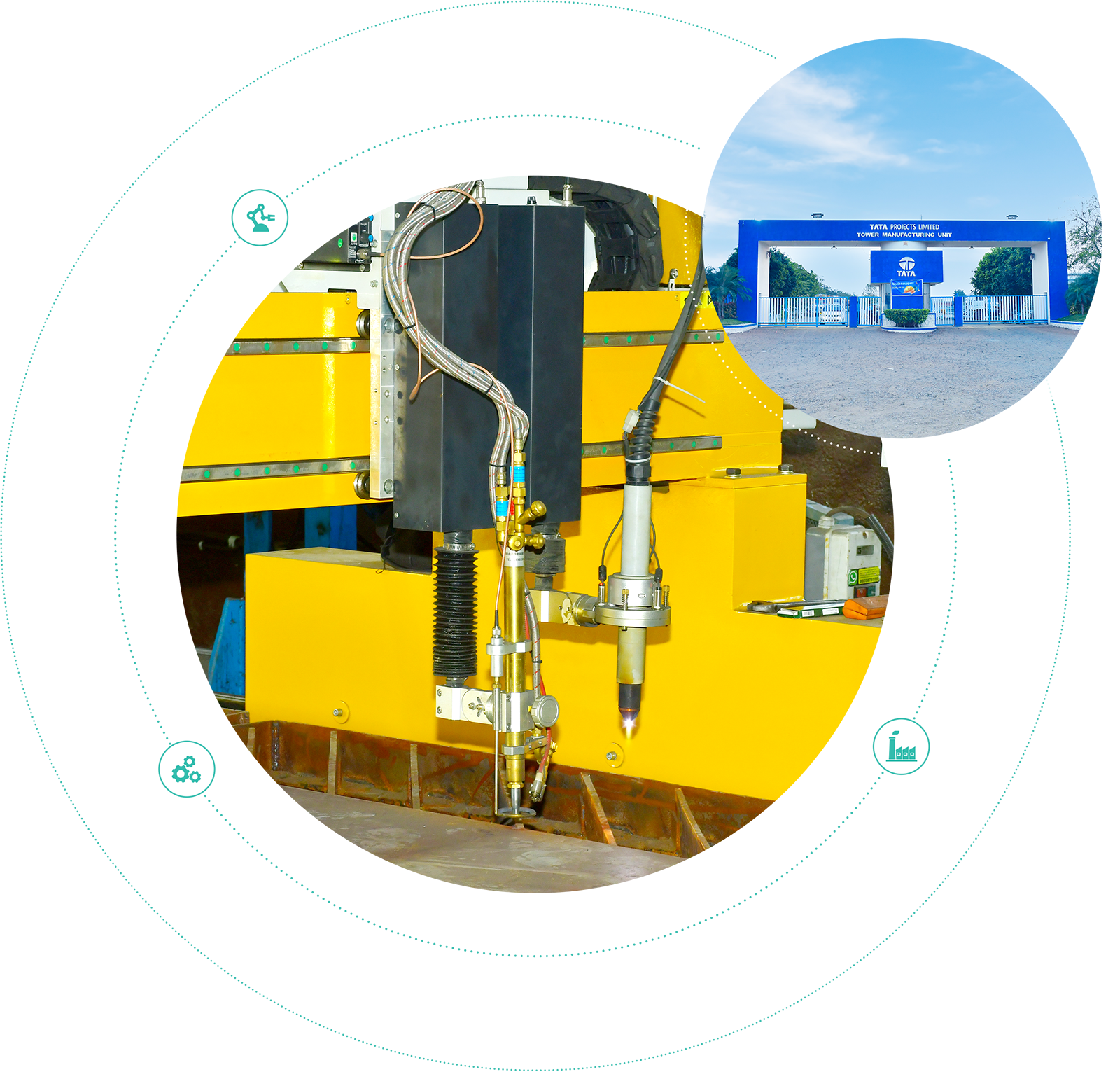

The Manufacturing Unit (TMU) Nagpur encompasses a large part of our Manufactured Capital. TMU exemplifies our commitment to high-quality infrastructure solutions. Meeting India’s demand for robust structures, TMU uses highly advanced technology and sustainable practices to ensure excellence with a focus on quality, safety, and innovation.

Key Highlights of FY2024

200 +

Construction Projects Completed

48 KTA

Galvanising Capacity

36 KTA

Tower Manufacturing Capacity

Launched a new structural steel fabrication product line in 2023

12 KTA

Structural Steel Fabrication Facility

Value Offerings

Towers Fabrication

Structural Steel Fabrication

Galvanisation

Automatic Blasting & Painting

SDGs Impacted

The Manufacturing Unit (TMU) Nagpur: Delivering Excellence Consistently

The Manufacturing Unit (TMU) Nagpur is a critical facility meeting India’s growing demand for high-quality structures and components. Our footprint extends beyond national borders, reflecting our commitment to excellence and innovation.

TMU Nagpur has supplied > 4,00,000 metric tons of material to major clients including Reliance Jio, Tata Teleservices, Power Grid India, PGCB Bangladesh, EEPL Ethiopia, Abengoa Peru, and EDEMSA, Argentina, till date.

Key Milestones

TMU introduced structural steel fabrication and hand railings in 2023

Quality, Safety, and Sustainability

Our state-of-the-art facility includes CNC machines and a semi-automatic Protherm galvanising plant, ensuring precision and efficiency in our manufacturing processes.

Our NABL-approved QA lab ensures high standards through rigorous testing and calibration processes. Equipped with advanced instrumentation, our lab performs comprehensive testing, including computerised universal testing, impact testing, hardness testing, chemical analysis, galvanising, and painting testing.

With an annual galvanising capacity of 48,000 Metric Tons, we adhere to the highest standards of quality and safety, as evidenced by our ISO 9000 / 14000 / 45000 certifications.

We invest in advanced safety equipment such as remote-controlled operated EOT cranes and battery-operated transfer trollies.

Our commitment to safety is paramount, with over ~18,500,000 safe man-hours recorded.

Additionally, our sustainability initiatives include a 990 KW solar energy capacity, reducing our carbon footprint and reliance on non-renewable energy sources.

1 Towers

Our diverse product range includes telecom towers, 66 KV to 765 KV towers, special purpose towers, OHE structures, swaged poles, railway structures, transmission towers, sub-station structures, and rural electrification structures.

We are proud to support the transmission of electricity to those who need it. We have delivered towers totalling ~4,00,000 metric tons and can manufacture transmission towers up to 765 KV. Our services include designing, type testing, manufacturing, and delivering international orders.

The production unit includes a 5,723 square meter covered area, 15,500 square meters for raw materials storage, and 13,500 square meters for finished goods storage. With advanced machinery for tower fabrication, we serve customers in Asia, Africa, and South America.

2 Structural Steel Fabrication

In 2023, we launched a new structural steel fabrication product line. Our 11,200 Sq. Mt. production unit features advanced machinery, including H Beam Welding, CNC Plasma Cutting, CNC Drilling, and a fully EOT-enabled plant with 12 cranes (20 MT capacity).

We have a capacity of over 12,000 MT per year and serve clients like NIAL, AMNS, DFCC, IOCL, ONGC, and NTPC. Our services include designing, procurement, fabrication, blasting, painting, and delivery. We can cut plates up to 100 mm and drill up to 75 mm, handling both built-up and hot-rolled sections.

3 Galvanisation

TMU features a state-of-the-art hot dip galvanising facility with a 1,937 Sq.M. covered plant shed. The zinc bath measures 10.5m in length, 1m in width, and 2.5m in depth, with a proven capacity of 48,000 MT per year.

TMU employs a seven-tank process and adheres to Pollution Control Board guidelines. The facility includes zinc and acid fumes extraction systems and an effluent treatment plant for waste acid and rinsing water, ensuring effective pollution control.

4 Shot Blasting and Painting

TMU boasts a state-of-the-art shot blasting and painting facility for heavy, medium and light-duty steel products, meeting both International and Indian standards. All techniques used are environmentally friendly.

Our production unit has a combined (Tower & Steel) manufacturing capacity of ~50 KTA.